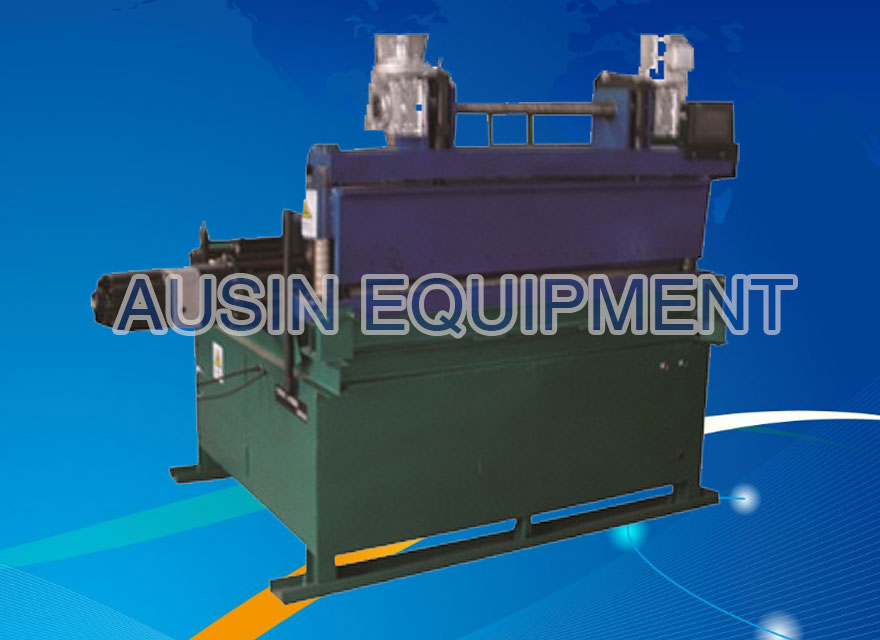

Swing shear V-Notch step lap transformer core cutting machine

V notch step lap transformer core cutting machine is special designed for notching V-shape on the silicon steel core laminations for transformer or reactors automatically.

Also cut the silicon steel to be kinds of shape, such as right angle, bevel angle, step lap etc.

Detailed introduction

Structure of Swing shear V Notching step lap core cutting machine:CRGO V notching machine is special designed for notching V-shape on the silicon steel core laminations for transformer or reactors automatically.

Also cut the silicon steel to be kinds of shape, such as right angle, bevel angle, step lap etc.

1. Inverter-controlled decoiler

2. Automatic center positioning & guiding devices

3. Swing cutting Device

4.Punching device

5. V notching device

6. Control system PLC

7. Belt transmitting table

8. Stacking table

Main technical data of transformer core V notching machine:

Main technical data of transformer core V notching machine:

|

No. |

Item |

Data |

|

1 |

Model Code |

JN-3003/4003/5003/6003-VC |

|

2 |

CRGO thickness |

0.23-0.6mm |

|

3 |

CRGO coil width |

30-600mm |

|

4 |

CRGO strip Length |

200-5000mm |

|

5 |

Cut-to-length tolerance |

+/-0.02mm |

|

6 |

Cutting angle tolerance |

+/-0.025° |

|

7 |

Hole position tolerance |

+/-0.1mm |

|

8 |

Burr height |

Less than 0.02mm |

|

9 |

Feeding speed |

Max. 100m/min |

|

10 |

Cutting speed |

25-50 pieces per minute |

|

11 |

Servo motors |

China famous brand/imported brand |

This machine also has step-lap function.1. Cutting power: adopts domestic famous brand inverter motor, high speed, low noise, long life.

2. Feeding power: adopts big torque AC servo motor, quick response, high precious positioning, low noise, small thermal braking, and long life.

3. Rail positioning: step motor, ball screw linear guide transmitting, central positioning, quick and precious.

4. Motion control: by advanced PLC, HMI operation, simple and convenient.

5. Lamination collecting: transmitting bell plus unloading rack.

6. Life assurance: Imported world famous linear guide and ball screw, high precious milling parts,

and high precision assembly, extend life of the machine.

Online order

Could not find any data!

You may also be interested in these...

Metal Cutting machine

this machine is mainly used for cutting metal coil leveling into strip and then cut to laminations.

The cutting material: silicon steel, CRGO, cold roll steel, galvanized steel, PPGI, SPTE, Tin pl...